Views: 0 Author: Site Editor Publish Time: 2025-07-17 Origin: Site

When you pick cold lamination vinyl, check if it works with your project. Look at the finish, thickness, and how strong it is. Think about how you will put it on. Cold lamination lets you cover prints, photos, or signs without heat. It gives a smooth and clean surface. The colors stay bright. Many people use cold lamination vinyl to protect their projects. It helps them last longer. You can also find eco-friendly and acid-free choices. These are good if you want your work to last a long time.

Pick cold lamination vinyl that works for your project. Think about the finish, thickness, and how strong it is. Cold lamination keeps prints safe without using heat. It helps colors stay bright and protects from scratches and UV rays. Choose the right laminate for your project. Use glossy for bright colors. Use matte if you want no glare when reading. Use textured if you need more grip. Clean and smooth the surface before you start. This helps stop bubbles and makes the vinyl stick better. Use pressure-sensitive adhesives for best results. Go slow and use tools like squeegees. This helps you get a smooth and long-lasting finish.

You may wonder how cold lamination works. It uses pressure instead of heat to protect your prints. You put your photo, poster, or sign between two layers of cold lamination film. Then, you press the layers together with a roller or laminator machine. The sticky side of the film grabs on right away. You do not have to wait for it to cool. This way, you can cover fragile items without hurting them. You can use it on paper, photos, or even fabric. It works for small crafts and big banners.

Tip: Cold lamination film is great for things that cannot handle heat. You will not melt or bend your project.

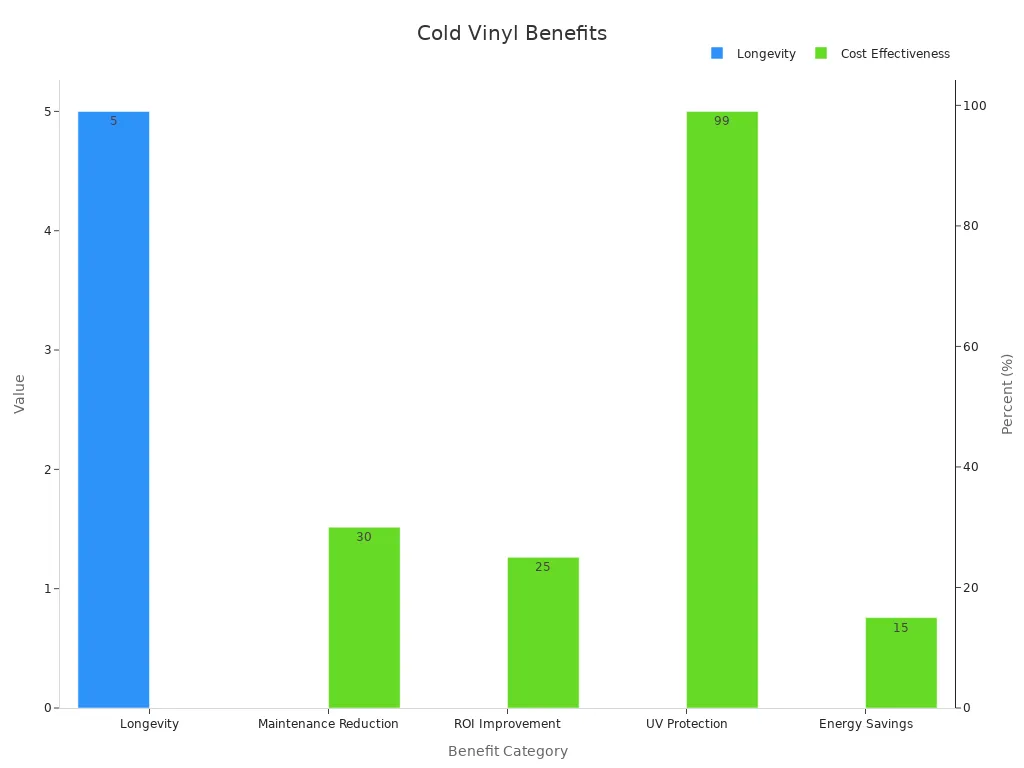

When you use cold lamination vinyl, you get more than a shiny layer. You help your project last for years. It blocks almost all UV rays, so colors stay bright. You will not need to clean or fix your project as much. Many people see about 30% less work to keep things nice. Businesses that use it for signs or menus often sell 25% more. Their displays look new and last longer.

Here's a quick look at the numbers:

Benefit Category | Quantifiable Evidence | Explanation |

|---|---|---|

Longevity | Up to 5 years without radical degradation | Cold lamination vinyl keeps things strong for many years. |

Maintenance Reduction | Up to 30% reduction in maintenance and replacement needs | Tough films mean you do not need to fix or replace as often. |

ROI Improvement | Sales growth up to 25% for businesses using long-term vinyl applications | Using it for a long time helps businesses sell more. |

UV Protection | Blocks up to 99% of UV rays | It keeps things safe from the sun and looking good. |

Energy Savings | Up to 15% reduction in energy costs | It helps buildings use less energy for heating or cooling. |

Application Success | Compliance with ASTM D6577 industry standard; high customer satisfaction | It works well in real life and people like the results. |

Flexibility in Design | Enables seasonal updates and quick design changes | Businesses can change their ads fast and keep customers interested. |

You can cover almost anything with it. You always get a smooth, neat look. Cold lamination film keeps your work safe from scratches and spills. It also lets you change designs quickly. If you want your projects to last, cold lamination is a smart pick.

You probably have a project in mind already. Maybe you want to protect a poster, make menus last longer, or create custom vinyl stickers for your business. Each project needs something different from cold lamination vinyl. If you work with photos, you want a film that keeps colors true. For school projects, you might want something easy to cut and apply. Vinyl stickers need a film that sticks well and resists scratches.

Here's a quick list to help you match your project to the right lamination:

Photos and Art Prints: Choose a clear, glossy finish for bright colors.

Menus and Signs: Pick a thicker film for durability.

Vinyl Stickers: Go for a scratch-resistant layer to keep designs sharp.

Crafts and Scrapbooks: Use acid-free film to protect memories.

Tip: Always test a small piece first. You can see how the film looks and feels before you cover the whole project.

Think about how many items you need to laminate. If you only have a few vinyl stickers or a single poster, you can use sheets and apply them by hand. For bigger jobs, like hundreds of menus or lots of stickers, rolls work better. They save time and give you a smoother finish.

Project Size | Best Lamination Option | Why It Works Well |

|---|---|---|

1-5 items | Sheets | Easy to handle, less waste |

6-50 items | Small rolls | Faster, more consistent |

51+ items | Large rolls | Best for bulk, saves money |

You can always scale up as your needs grow. If you start with a few vinyl stickers, you might move to bigger batches later. Cold lamination vinyl gives you flexibility for any project size.

You might wonder how thick your laminate should be. Thickness matters a lot. It changes how your project feels and how long it lasts. You measure laminate thickness in mils. One mil equals 0.001 inch. Thicker films give more protection, but they also make your project stiffer. Thinner films bend easier and cost less.

Here's a quick table to help you pick the right thickness:

Thickness (mils) | Characteristics & Recommended Uses |

|---|---|

1.5 | Thin, flexible; economical; good for business cards, labels, decals, temporary items. |

3 | Balanced protection and flexibility; works for foldable items like menus, manuals, posters. |

5 | More rigid and durable; handles frequent use; best for charts, bookmarks, event passes. |

If you want to fold your project, stick to 3 mil or less. For something you handle a lot, like bookmarks or passes, go for 5 mil. Sometimes, using heavier paper with a thin laminate saves money and still gives strength.

Tip: Home laminators usually handle up to 3 or 5 mil. If you need thicker film, check your machine first.

You get the best laminate for vinyl stickers when you match thickness to how you use them. Stickers for water bottles or laptops need a sturdy layer. Labels for short-term use can stay thin and flexible.

Now, let's talk about how your project looks and feels. The finish changes everything. You can pick from glossy, matte, or textured laminate. Each one has a job.

Glossy: This finish shines. It makes colors pop and helps enhance colour vibrancy. Use it for photos, art prints, or anything you want to stand out. Glossy laminate works well indoors.

Matte: Matte stops glare. It feels smooth but not shiny. If you use your project in bright light or outdoors, matte is your friend. It keeps things easy to read. Many people say matte is the best laminate for vinyl stickers used on windows or menus.

Textured: This finish adds grip. It hides fingerprints and scratches. You see it on things people touch a lot, like event passes or instructional charts.

Here's a quick list to help you choose:

Want bright colors? Go glossy.

Need to cut glare? Pick matte.

Expect lots of handling? Try textured.

Note: Matte laminate is perfect for classrooms, offices, or outdoor signs. It keeps things clear even in sunlight.

Cold lamination vinyl gives you all these choices. You get pressure-sensitive adhesives that protect prints without heat. They work on many inks and media types. You can use them for banners, stickers, or even menus. The best cold lamination film always matches your project's needs.

When you prepare your surface, make sure it's clean and flat. This helps your laminate stick well and last longer. If you want the best laminate for vinyl stickers, always start with a smooth, dust-free base.

You want your projects to last. Cold lamination film gives you that extra shield. It blocks out harmful UV rays. This keeps your colors bright and stops fading. You can hang your signs in the sun and not worry about them turning dull. The film also stands up to scratches. Kids, pets, or busy hands cannot ruin your work easily.

Let's look at how well these films protect your items:

Test Type | Parameters | Observations / Results |

|---|---|---|

Pencil Scratch | Hardness: 6B, Weight: 500 g | Trapezoid prism structure showed best scratch resistance with minimal distortion; nanopillar structure showed worst resistance with pillars squashed and adhered. |

Sand Blasting | Particle size: <350 µm, Speed: 1.4 m/s | Triangular and trapezoid prism microstructures had better sand resistance; nanopillar structures collapsed after test. |

Bending Test | Cycles: 10,000, Angle: 0°–180° | Micro/nanostructures remained intact, indicating outstanding flexibility and stability. |

You can see that cold lamination film stands up to tough tests. It keeps its shape even after thousands of bends. The surface does not scratch or wear down fast. This means your menus, posters, or stickers stay looking new. If you want maximum protection, pick a film with strong microstructures. You get peace of mind and save money on replacements.

Tip: Use cold lamination for outdoor signs or items that get handled a lot. It keeps them safe from sun and scratches.

You care about the planet and your memories. Many cold lamination films use acid-free materials. Acid-free means your photos and art will not turn yellow or break down over time. You can trust your keepsakes to stay safe for years. This is important for scrapbooks, family photos, or school projects.

Eco-friendly options help you lower your impact on the environment. Some films use recycled materials. Others skip harsh chemicals. You can recycle many cold lamination films after use. This makes them a smart choice for green projects.

Here's why you might choose cold lamination over hot lamination:

Cold lamination uses less energy. You do not need to heat up a machine.

It works faster. You can laminate right away, no waiting for things to cool.

You avoid fumes or burns. It feels safer, especially for kids or classrooms.

Many cold lamination films cost less than hot ones. You save money and help the earth.

Note: If you want the best cold lamination film, look for acid-free and eco-friendly labels. You get strong protection and help the planet at the same time.

You can trust cold lamination to keep your projects safe, bright, and green. It gives you flexibility and peace of mind. You get to enjoy your work longer and feel good about your choices.

You want your cold lamination vinyl to match your project. Not all surfaces are the same. Some grab the laminate fast. Others need more care. You can use laminate on paper, cardstock, photos, and most plastics. Vinyl stickers work best on smooth, clean surfaces. If you try to laminate stickers on rough or dusty things, you might see bubbles or peeling.

Here's a table to help you check your material:

Material Type | Works Well? | Notes |

|---|---|---|

Paper | ✅ | Clean, dry, and flat is best |

Cardstock | ✅ | Handles thicker laminate |

Vinyl stickers | ✅ | Smooth finish, strong bond |

Fabric | ⚠️ | Test first, may not stick |

Metal | ⚠️ | Needs special prep |

Wood | ⚠️ | Seal first for best results |

Tip: Wipe your surface before you start. Dust or oil can stop the laminate from sticking.

Pressure-sensitive adhesives make cold lamination simple. You do not need heat or special tools. Just press the laminate onto your project and it sticks. These adhesives work well for vinyl stickers, posters, and menus. You get a strong hold that lasts.

Tests show some adhesives, like 2-part polyurethane, make your project stiffer. They also handle temperature changes better than others. This means your laminate stays flat and clear, even outside or in busy places. Some adhesives, like UV-acrylate, let you work fast and stay flexible. Both types are strong, but polyurethane is best for long-term projects.

Humidity or how fast you press can change your results. If you want the best laminate for vinyl stickers, pick a film with a good adhesive. It keeps your designs safe from peeling or fading. When you laminate, press hard and smooth out air bubbles. This helps your project look neat and last longer.

Use pressure-sensitive adhesives for:

Posters and signs

Laminating stickers

Vinyl stickers for water bottles or laptops

Menus and charts

You get an easy process and strong results. Cold lamination vinyl lets you protect almost any project.

You want your project to look smooth and last a long time. Start by cleaning your surface. Dust, oil, or even a tiny crumb can cause problems. Use a soft cloth or a lint-free wipe. Make sure everything feels dry and flat. If you see any bumps, press them down or smooth them out.

Here's a quick checklist to help you get ready:

Wipe the surface with a clean, dry cloth.

Check for dust or lint.

Make sure the area is flat and free from wrinkles.

Let everything dry before you start.

Tip: If you work with vinyl stickers, always check the backing. Sometimes, a little static attracts dust. A quick wipe can save you trouble later.

No one likes bubbles under their laminate. They make your project look messy. You can avoid them if you go slow and use the right tools. Many people use a squeegee or even a credit card. Start at one edge and press down as you go. Move slowly and push air out to the sides.

Here's a simple step-by-step guide:

Peel back a small part of the laminate.

Line up the edge with your project.

Press down with a squeegee or card.

Move across the surface, pushing out air.

If you see a bubble, lift the laminate and try again.

A table can help you remember what works best:

Tool | Why Use It? |

|---|---|

Squeegee | Firm pressure, no marks |

Credit Card | Easy to find, works well |

Soft Cloth | Gentle, good for photos |

Cold lamination works better than hot lamination for vinyl stickers. You get less warping and more durability. Products like Oraguard 651 give you scratch resistance and UV protection. If you're new, try self-adhesive sheets from Avery. They make things easier for beginners.

Take your time. Practice helps you get perfect results. Soon, you'll have smooth, bubble-free projects every time.

When you choose cold lamination vinyl, remember these things:

Compatibility: Check if it works with your project's material.

Finish: Pick glossy, matte, or textured for the look you want.

Thickness: Thin is bendy, thick is strong. Choose what you need.

Durability: Find one that blocks UV and stops scratches.

Eco-friendliness: Pick acid-free or recycled to help the planet.

Application: Use the right way for how many you need to do.

The right cold lamination film makes your work look great and last longer. Be confident in your pick and enjoy how it turns out!

You can use scissors or a craft knife. For straight lines, a ruler helps. Always cut slowly. Sharp blades give you clean edges. If you want perfect shapes, try a cutting machine.

Yes, you can write on them. Use permanent markers for best results. Dry-erase markers work on some finishes. Test a small spot first.

Tip: Permanent markers stay on glossy finishes. Dry-erase markers wipe off matte or textured films.

Keep it flat or rolled in a cool, dry place. Avoid sunlight. Store it in a resealable bag if possible. This keeps dust and moisture away.

Storage Method | Good For | Not Good For |

|---|---|---|

Flat | Sheets | Large rolls |

Rolled | Rolls | Small scraps |

Bagged | All types | Wet areas |

Yes, it works well outside. It protects against sun, rain, and scratches. For best results, pick a film with UV protection. Your signs and stickers will last longer.