Views: 0 Author: Site Editor Publish Time: 2025-07-21 Origin: Site

You use cold lamination vinyl for lots of projects. It protects your prints, but you may see bubbles or wrinkles. Sometimes, the lamination looks uneven or starts to peel. You might notice a foggy look or sticky glue left behind. The edges can also have problems. Cold lamination can make the film shrink if the weather changes. Laminating gets hard when these problems show up. You want easy steps to fix each problem. You also need a simple checklist to solve things fast.

Make sure your workspace and prints are very clean before you start laminating. This helps stop bubbles, peeling, and sticky messes.

Use the right amount of pressure and heat. Pick a good film to stop wrinkles, uneven spots, and shrinking.

Keep your room at the right temperature and humidity. This helps the lamination stay smooth and clear. It also stops it from looking foggy or cloudy.

If you see bubbles or wrinkles, gently lift the film and smooth it out. Use tools like squeegees or rulers to help fix it.

Use a troubleshooting checklist if you still have problems. Ask an expert for help if you need it. This will help your projects look neat and last longer.

Bubbling happens a lot when you laminate prints. The main reasons are dust, uneven pressure, bad tools, and the room's air. Dust or dirt on your print traps air under the film. If you press too hard or not enough, air pockets form. Cheap rollers or squeegees do not press the film flat. Wetness under the film can also make bubbles and creases. If the room is very humid or the temperature changes a lot, you get more problems. Using the wrong glue or not cleaning first lets air get trapped and causes blisters.

A study showed that bad lamination can make holes and bubbles in the glue. These problems can be between 3 mm and 15 mm wide. They make the glue weaker and your project less strong. The table below shows how these problems hurt your work:

Aspect | Details |

|---|---|

Defect Types | Voids, porosity, air bubbles in adhesive layers |

Cause | Improper adhesive application, contaminants, trapped air |

Void Size Range | 3 mm to 15 mm diameter |

Impact on Bond Quality | Voids reduce adhesive strength and damage the bond |

You can use different ways to fix air bubbles. Try a squeegee or a flat ruler. These tools help push air out to the edges. Start in the middle and move out. Press down with the same force as you go. If you see bubbles or creases, lift the film and try again. Clean before you start. Wipe the print with a lint-free cloth. Keep your workspace clean. If you find small bubbles after, poke them with a pin and press the air out.

Tip: Always check your rollers for damage. Bad rollers press unevenly and make more bubbles.

You can stop bubbles and creases by doing a few things:

Clean your print and the area before you start.

Let prints dry all the way so no water gets trapped.

Set your laminator to the right pressure. Too much or too little makes bubbles.

Let the film relax before you use it. This stops stretching.

Use films made for dry use to stop problems.

Adjust rollers so they press evenly.

Work in a clean, dry room to keep dust and water away.

Studies show these steps lower the number of bubbles in your projects. You can also use special films to check roller pressure. This helps you find uneven pressure before it causes trouble. Good cleaning and the right steps keep your work smooth and strong.

You often see wrinkles and creases when laminating. These imperfections can ruin the look and strength of your project. Many things cause them:

Incorrect temperature settings create bubbles and creases by not activating the adhesive right.

Uneven roller pressure stretches or bunches the film, making creases.

Poor feeding techniques fold or overlap the film.

Moisture trapped inside forms steam bubbles during heating.

Low-quality film with uneven adhesive or wrong thickness leads to bubbling and creasing.

Studies show that wrinkles can lower the strength of laminated materials by up to 40%. Some tests even found a two-thirds drop in fatigue life when wrinkles appeared. These imperfections often start from mistakes during laminating or from using bad materials.

You can fix wrinkles and creases by using the right techniques. Start by checking your laminator's temperature and pressure settings. Make sure they match the film you use. Feed the film slowly and evenly. If you see bubbles and creases, stop and lift the film gently. Smooth it out before you continue. Use a squeegee to press out air and flatten the film. Replace old or damaged rollers. Choose high-quality film to avoid imperfections.

A new modeling method helps predict where wrinkles might form. This lets you adjust your process before problems start. Tests show that using these techniques can cut the risk of wrinkles by more than 30%.

You can prevent wrinkling by following a few simple steps:

Store your film flat and in a cool, dry place.

Let your prints adjust to room temperature before laminating.

Clean your workspace to keep dust away.

Set your laminator to the right speed and pressure.

Use slow, steady feeding to avoid folds.

Pick films made for your project.

Many studies agree that these steps help prevent wrinkling. You get better results and fewer imperfections. When you use the right techniques, you avoid bubbles and creases and keep your work looking sharp.

Uneven lamination happens when your project looks patchy or does not stick well. This problem can start before you even begin to laminate. Many things can cause it. The table below shows the main reasons and how experts check for them:

Documented Cause | Supporting Measurement or Report Methodology |

|---|---|

Temperature variations during pre-nip heating | Surface temperature checks using pyrometers or thermal imaging; temperature strips inside dummy laminates |

Uneven nipping forces | Pressure-sensitive films inside dummy laminates; pneumatic gauges; manual nip-roller adjustments |

Glass distortion and contamination | Visual inspection under good lighting; checking for contamination or glass distortion |

Improper assembly and trimming | Inspection of assembly methods; questioning trimming techniques for over-stretching or contamination |

Washing and water quality | Monitoring water quality and circulation; regular maintenance of demineralized water systems |

Clean room conditions | Continuous recording of airflow, humidity, temperature, and filter status |

Autoclave defects | Monitoring autoclave temperature and pressure; reviewing maintenance records; observing pressure and cooling cycles |

Equipment maintenance issues | Regular checks on nip-roller mechanics, autoclave function, and heating elements |

You might see uneven lamination if your equipment is old or not taken care of. Rollers that press unevenly or changes in temperature can also cause this. Dirty surfaces or bad water during cleaning make it worse.

You can fix uneven lamination by following some easy steps. First, check your equipment. Make sure rollers press evenly on the whole surface. Set the right temperature for your film. Clean all surfaces before you start. If you see uneven spots, stop and look at your process.

Use pressure-sensitive films to check for uneven pressure.

Adjust nip-rollers and look for worn parts.

Keep your workspace clean and control the room's temperature and humidity.

Change out damaged or bad film.

Studies in other fields, like dental laminates, show that planning and good technique work well. One study found that partial laminate veneers lasted a whole year and over 95% lasted five years. This shows that good prep and teamwork are important.

Tip: Always test your setup with a sample before you start a big project. This step helps you find problems early.

You can stop uneven lamination by making good habits part of your routine:

Store your film flat and away from heat or wet places.

Let all materials warm up to room temperature before you start.

Clean your workspace and tools every time.

Check your equipment for even pressure and that it works right.

Watch the temperature and humidity in your work area.

Doing regular checks and setting up carefully helps a lot. When you follow these steps, you avoid most problems and get smooth, even results every time you laminate.

Sometimes, the edges of your laminated project start to peel up. This happens when the adhesive does not stick well. Dust, oil, or water on your print can make the glue weak. Using cheap film or pressing too softly can also cause this. If you cut the edges right after laminating, the film may not be set. Changes in temperature or humidity can make peeling worse. When the room gets hot or cold, the film and glue move differently. This movement can pull the edges up.

You can fix peeling edges with a few easy steps. First, press the edges down with a squeegee. Start in the middle and push toward the edge. If the edge still comes up, use a hair dryer to warm it. The heat makes the glue softer and helps it stick. Press the edge down again while it is still warm. If the edge keeps lifting, cut off the loose part. Put clear tape or extra lamination film over the spot.

Researchers found peeling works better than pulling straight up. If you peel the edge slowly and at an angle, the glue breaks more gently. This way works for both people and robots. In tests, robots peeled film off without tearing or delamination. You can do the same by lifting one edge and peeling it back slowly if you need to remove or fix the film.

Tip: Let your laminated project sit for a few hours before cutting the edges. This helps the glue set and stops peeling.

You can stop peeling by doing these things:

Clean your print and hands before you start.

Use good lamination film.

Press all the edges with even pressure.

Wait before you cut the edges.

Keep finished projects in a dry, safe place.

Here is a table to help you remember:

Step | Why It Helps |

|---|---|

Clean surfaces | Gets rid of dust and oil |

Use good film | Glue sticks better |

Press edges firmly | Makes a strong bond |

Wait before cutting | Glue has time to set |

Store properly | Stops water from causing problems |

If you follow these steps, your projects will look neat and last longer. You can stop most peeling before it starts.

Sometimes, your laminated project looks foggy or cloudy. This usually happens because of moisture. If the air is very humid, water can get trapped inside. The glue and film do not work as well. Cold lamination in a damp room makes the film not stick right. You see a cloudy look instead of clear.

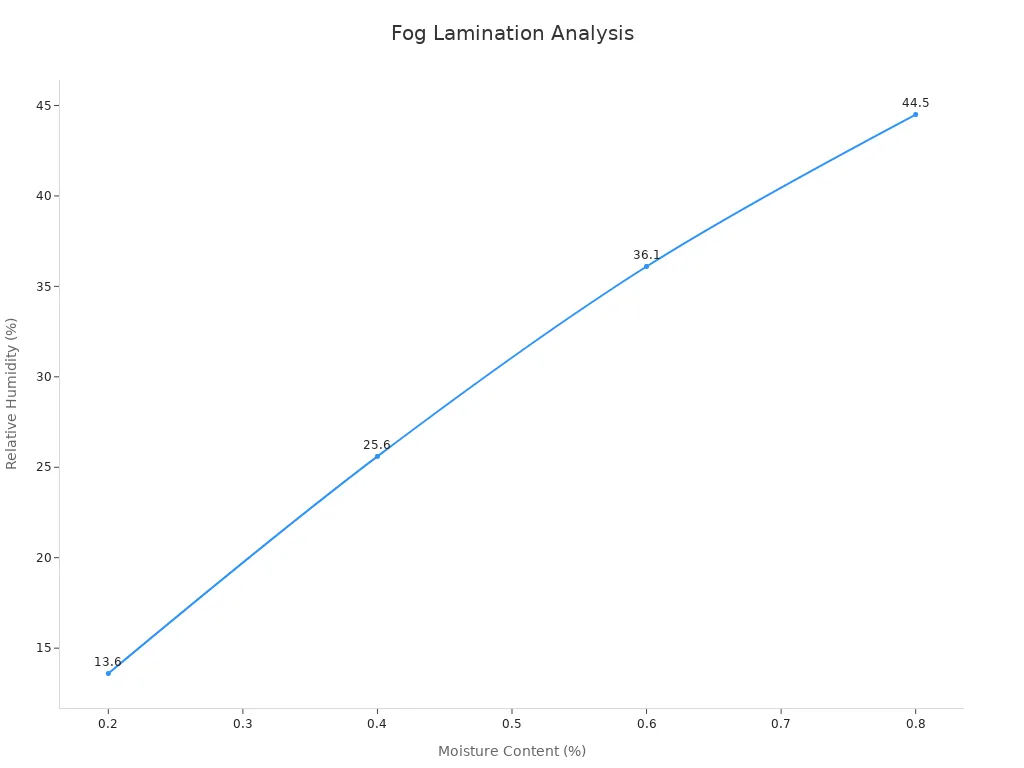

Wet film or a wet print can also cause this. If you do not let your print dry, water stays under the film. The glue cannot stick well. This gives you a foggy finish. The table below shows how more humidity makes the film weaker:

Moisture Content in PVB (%) | Relative Humidity (%) | Cohesive Strength | Interfacial Fracture Energy |

|---|---|---|---|

0.2 | 13.6 | Baseline | Baseline |

0.4 | 25.6 | Decreases | Decreases |

0.6 | 36.1 | Decreases | Decreases |

0.8 | 44.5 | -70% | -50% |

Note: When humidity goes up, the film gets weaker. You see more foggy spots.

You can fix a foggy finish with some easy steps:

Let your prints dry before you start.

Use a dehumidifier in your work area.

Keep your film in a dry spot.

Press the film down with even force.

If you see fog after you finish, use a hair dryer to warm the film. This helps the water leave. Press the film again with a squeegee. Some films have special coatings that stop fog. These coatings are used in many places. They help food packages, goggles, mirrors, and car windows stay clear. The table below shows how antifog solutions help:

Category | Details and Benefits |

|---|---|

Material Types | Polyester, BOPP, and polycarbonate films resist fog and stay clear |

Technologies | UV and aqueous coatings, surfactants, and photocatalysts improve antifog performance |

Applications | Food packaging, agriculture, visors, mirrors, windows, solar panels, and displays |

You can stop foggy finishes by keeping your workspace dry. Always let your prints and film get used to the room. Store your supplies in closed containers. Use films made for wet places. Check your room's humidity before you start. If you see water, wait or use a dehumidifier.

Tip: Clean your tools and hands before you start. This keeps water and oil away from your project.

When you follow these steps, your lamination stays clear and looks good.

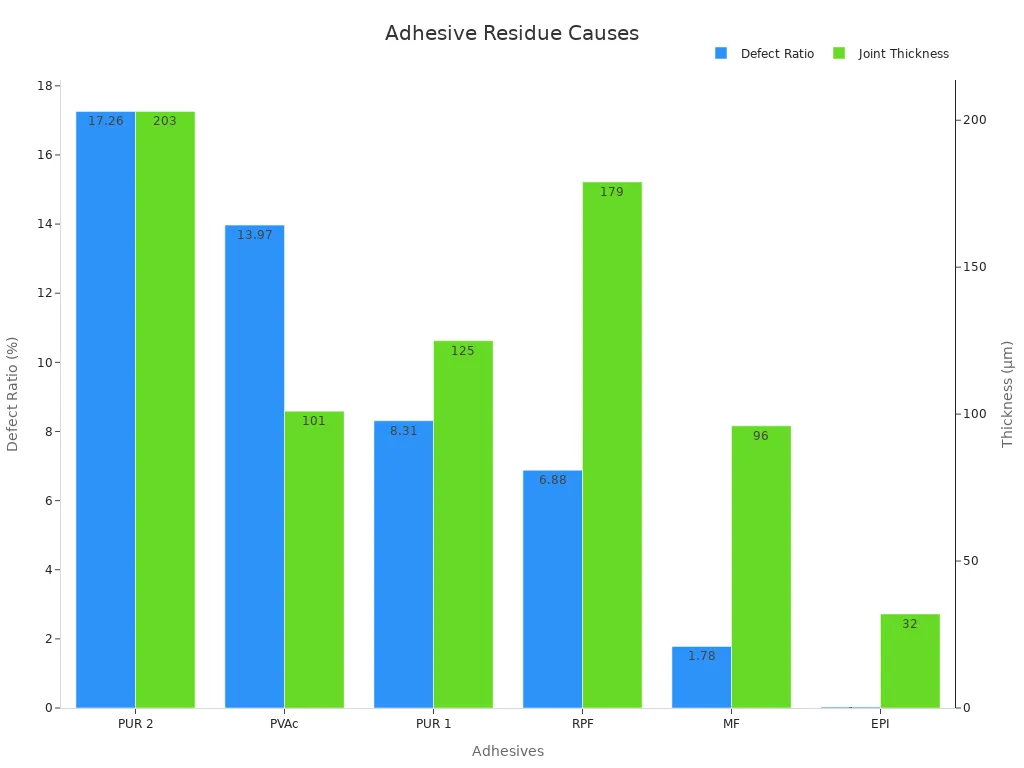

Adhesive residue often appears after you finish laminating. It looks like sticky spots or smears left behind on your project. This problem happens when the glue does not cure right or when the film is too thick. If you use too much adhesive, it can seep out and leave a mess. Voids or air pockets inside the glue layer also cause residue. Some adhesives, like PUR and PVAc, create more residue because they have thicker joints and higher defect volume ratios.

Here is a table showing how different adhesives compare:

Adhesive | Defect Volume Ratio (%) | Adhesive Joint Thickness (µm) |

|---|---|---|

PUR 2 | 17.26 | 203 ± 6 |

PVAc | 13.97 | 101 ± 5 |

PUR 1 | 8.31 | 125 ± 4 |

RPF | 6.88 | 179 ± 6 |

MF | 1.78 | 96 ± 4 |

EPI | 0.03 | 32 ± 2 |

You see that adhesives with thicker joints and higher defect ratios leave more residue. The way you cure the glue and the solid content also play a role.

You can remove adhesive residue using several proven methods. Try these steps:

Use rubbing alcohol on a soft cloth to lift sticky spots.

Apply warm vinegar for stubborn residue.

Heat the area with a hairdryer to loosen glue on glass or plastic.

Mix baking soda and coconut oil for wood or delicate surfaces.

Soak washable items in warm soapy water.

Try commercial removers like Goo Gone for tough residue.

Use olive oil and dish soap for wooden surfaces.

For appliances, use rubbing alcohol or stainless-steel cleaner.

Freeze fabric items to harden glue, then scrape it off.

Rub peanut butter on non-porous surfaces to break down glue.

Tip: Always test your cleaning method on a small spot first. Use soft cloths to avoid scratching your project.

Many experts recommend combining chemical and mechanical methods. For example, you can apply rubbing alcohol, let it sit, then gently scrape the residue away. Soaking in hot water with OxiClean works well for jars and glass.

You can stop adhesive residue before it starts. Use the right amount of adhesive and avoid thick glue layers. Choose high-quality lamination film. Let the glue cure fully before you handle or cut your project. Keep your workspace clean and dry. Store your supplies in sealed containers. If you follow these steps, you will see less sticky residue and spend less time cleaning.

You may notice your cold lamination film shrinking or warping after you finish a project. This problem often starts because of heat, how you handle the film, or the environment in your workspace. When you use the wrong temperature or leave the film in a hot room, the material can change shape. The way you package or store the film also matters. Some films have additives that make them less stable. If you stretch the film too much, it can create tiny defects that lead to shrinkage. The table below shows the main causes and how they affect the film:

Cause/Factor | Description and Impact on Film Shrinkage and Warping |

|---|---|

Thermal Processing Conditions | High temperature and long heating time make the film softer and easier to deform. |

Packaging Methods | Vacuum or tight packaging can change how heat moves through the film, causing stress and shrinkage. |

Additives | Some chemicals in the film can stop the material from staying flat. |

Film Intrinsic Properties | Films with more crystals stay stable, but some films have weak spots that shrink faster. |

Mechanical Processing | Stretching the film in two directions makes it strong but can add tiny cracks that lead to warping. |

Environmental Impacts | Hot or humid rooms make the film change shape more easily. |

You can fix or reduce shrinkage by using the right steps. Choose a cold lamination film that matches your project needs. Store your film in a cool, dry place. Handle the film gently to avoid stretching or bending. When you laminate, use the correct temperature and pressure. If you see wrinkles or warping, try these tips:

Let the film rest at room temperature before you use it.

Use slow, even pressure when applying the film.

Avoid exposing the film to direct sunlight or heat.

Test a small piece before you start a big project.

Researchers have measured how film changes during shrinking. They found that careful handling and the right settings can lower the risk of shrinkage. They also saw that films with the right thickness and fewer defects shrink less and stay smooth.

Tip: Always check your film for damage before you start. Small cracks or folds can turn into big problems after lamination.

You can prevent most shrinkage problems by making smart choices. Pick a cold lamination film with good thermal stability. Keep your workspace at a steady temperature and humidity. Store your film flat and away from heat. Use gentle hands when moving or cutting the film. Regularly check your tools and laminator for even pressure. When you follow these steps, your projects will look better and last longer.

You want to fix lamination problems quickly. A troubleshooting checklist helps you find the problem step by step. It tells you what to check in your process. This is better than guessing or changing things randomly. The table below shows common problems and what to check first.

Problem | What to Check First | Next Step | Final Action |

|---|---|---|---|

Bubbling | Cleanliness of surface | Roller pressure | Use squeegee to smooth |

Wrinkling | Film storage conditions | Feeding speed | Adjust laminator settings |

Uneven lamination | Roller alignment | Temperature consistency | Replace damaged film |

Peeling edges | Adhesive quality | Cutting timing | Press edges firmly |

Foggy finish | Humidity in workspace | Print dryness | Use dehumidifier |

Adhesive residue | Amount of glue used | Film thickness | Clean with alcohol |

Film shrinkage | Room temperature | Film handling | Store film flat |

Note: This checklist gives you clear steps to follow. Check each part, fix what you find, and write down your results. This helps you remember what works and share it with others.

A checklist like this stops you from making random changes. You can look for easy mistakes, like wrong settings or dirty tools. You also keep notes, so you get better at fixing problems.

Sometimes, you try every step but still have trouble. You might see the same problem again and again. If you cannot find the reason, ask for help. Call a technician or talk to your supplier. They know more ways to fix things and can check your tools. If your laminator or film looks damaged, get help right away. If you feel stuck, do not keep guessing. Getting expert help saves time and keeps your projects looking good.

You get the best results from cold lamination vinyl when you use the right technique, keep surfaces clean, and choose quality materials. Most problems stay away when you follow these steps:

Clean your workspace and tools.

Use the troubleshooting checklist.

Pick high-quality film.

Remember: You can fix or prevent most issues. If a problem keeps coming back, ask an expert for help. Your projects will look better and last longer.

You should check your workspace for dust. Clean your rollers and prints. Try using a squeegee to push out air. If bubbles still appear, switch to a higher-quality film. You can also test your laminator settings.

You can fix small wrinkles by gently lifting the film and smoothing it back down. Use a squeegee or ruler. For large wrinkles, you may need to re-laminate. Always work slowly to avoid new creases.

Humidity or moisture causes a cloudy look. Wet prints or a damp room can trap water under the film. Always let your prints dry. Store your film in a dry place. Use a dehumidifier if needed.

Try rubbing alcohol on a soft cloth. For tough spots, use warm vinegar or a commercial remover. Always test a small area first. You can also use baking soda and oil for delicate surfaces.

Tip: Clean your tools after each project. This helps prevent sticky residue next time.